Project

Context

Thermal energy storage (TES) is a key element for effective and efficient generation, and for utilization of heat when heat supply and heat demand do not match spatially and in time. This covers effective thermal management in the sectors of heating and cooling, process heat and power generation as well as increased utilization of renewable energy systems. A specific feature of thermal storage systems is that they are diversified with respect to temperature, power level and use of heat transfer fluids and that each application is characterized by its specific operation parameters. Thus, the availability of a broad portfolio of storage materials and design concepts is needed.

Applications of TES systems are expected in several areas such as: solar heating and cooling of buildings; power generation using thermal conversion processes; seasonal storage in combination with district heating systems; etc.

- Heat can be stored essentially in three ways:

sensible heat storage, which results in an increase or decrease of the storage material temperature;

latent heat storage, which is connected with a phase transformation of the storage materials (phase change materials - PCMs), typically from solid to liquid and vice versa;

thermochemical heat storage, which is based on reversible endo/exothermic chemicalreactions.

Currently commercially available TES systems are solely sensible heat storage systems to be used in connection with single phase heat transfer fluids. The technology of latent heat storage is today still a subject of Research and Development (R&D), with few specialists on the market that are familiar with designing and producing complete latent storage systems. Thermochemical storage is still in a fundamental laboratory stage of development.

Improving relevant thermo-physical properties of Phase Change Materials (PCMs) and thermo-chemical storage materials by use of special additives or by developing composites has been recognized as one of the scientific challenges to close the gap between the TES targets and present performances. Additives and more specially carrier materials can efficiently contribute to enhance heat and/or mass transfer, to improve thermo-mechanical stability, to prevent undesirable effects like segregation or undercooling in PCMs, and to improve cyclability.

Objectives

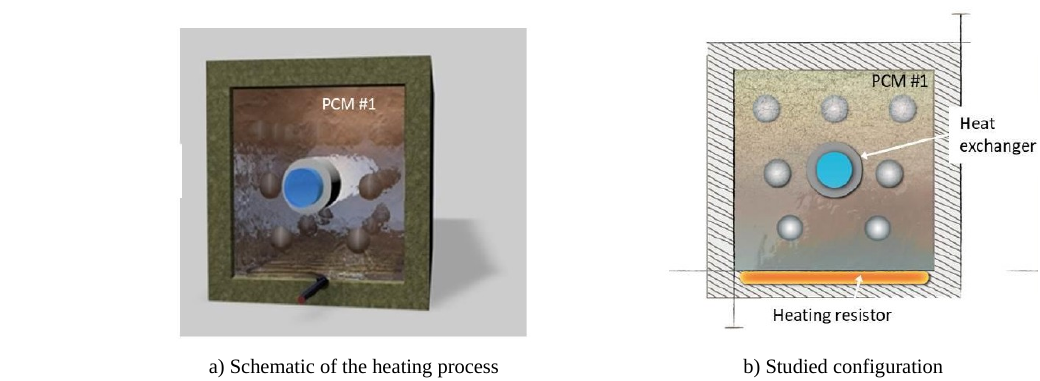

In this project, we propose to study efficiency in term of energy storage of adding spheres embedded in a PCM as well as their spatial optimization. In the proposed project we assume that the density of the enhancers allows a balance with those of PCM1 to keep them at the quasi-same positions (see figure 1) despite the reversible liquid/solid transitions (Archimedes' principle).

Figures 1: Simplified schematic of the heating process. In the center, the heat transfer fluid through the heat exchanger is colored in blue. White spheres are solid conductors.

From the industrial point of view, two configurations can be considered. The first one is made up with a number of full solid spheres with the appropriate size, thermal conductivity and density (see figure 1.a). The second one is made up with number of hollow spheres fulfilled with the same PCM as the one used outside or with a different PCM (see figure 1.b). The macrosegragation related to solid fraction shrinkage will not be considered in these cases. Figure 1.c shows a simplified schematic of the heating process through the bias use of a heat exchanger. The steam is at the temperature required for the solid/liquid phase change.

- In the context of the two configurations in Figures 1.a and 1.b, the ultimate objective of the project is to propose and analyse efficient and “easy-to-implement” algorithms for

the simulation of the phase change process (energy and motion)

the optimization of the location and the size of the enhancers in order to accelerate the melting process and the loading/unloading process.

For both objectives we aim at providing solutions using full order methods (FOM) and reduced order methods (ROM). Indeed, since the optimization iterative process requires to solve the problem numerically and repeatedly, the computational procedure becomes very time consuming, and a large amount of memory storage is needed. This is the reason why to build efficient and robust ROMs is compulsory.

This project includes modelling, theoretical, numerical and experimental developments. A specific work ackage is dedicated to experimental implementation to validate some achievements.